Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

Dry bulk liner is the smartest idea ever for intermodal dry bulk transport, it has been seen as a very efficient and cost-effective alternative to shipping in small packaging such as FIBC, small parcel with capacity ranging from 25kgs to 100kgs and pallets.

Compared to traditional dry bulk transport patterns, containerized dry bulk transport is reducing logistics cost, improving logistics efficiency, and lessen the impact to our environment.

LAF offer Dry Bulk Liners with PE, PP, HDPE, Aluminum materials, and can also design the liner according to container type, physical and chemical properties of cargo, and loading and unloading equipment.

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin,PP resin, PET pellets,PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products

LAF is a worldwide leading manufacturer of economic dry bulk liners, with cutting edge production techniques, offering full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Comprehensive silo-to-silo dry bulk transport solution is designed to suit specific requirements of each client.

It usually starts with a comprehensive assessment of production, storage and transportation of a factory. With senior experience and expertise in bulk commodity supply chain, and our team at LAF DRY BULK LINER DEPT. helps client to optimize their dry bulk logistics cycle with tailor-made dry bulk liners, assistance in development of dry bulk handling equipment for load and unload containers with dry bulk commodities.

● Maximally utilize container space

● Save packaging cost

● Easy to set up

● Can be tailor-made to various containers, e.g. 20’GP, 40’GP, 35’ containers etc.

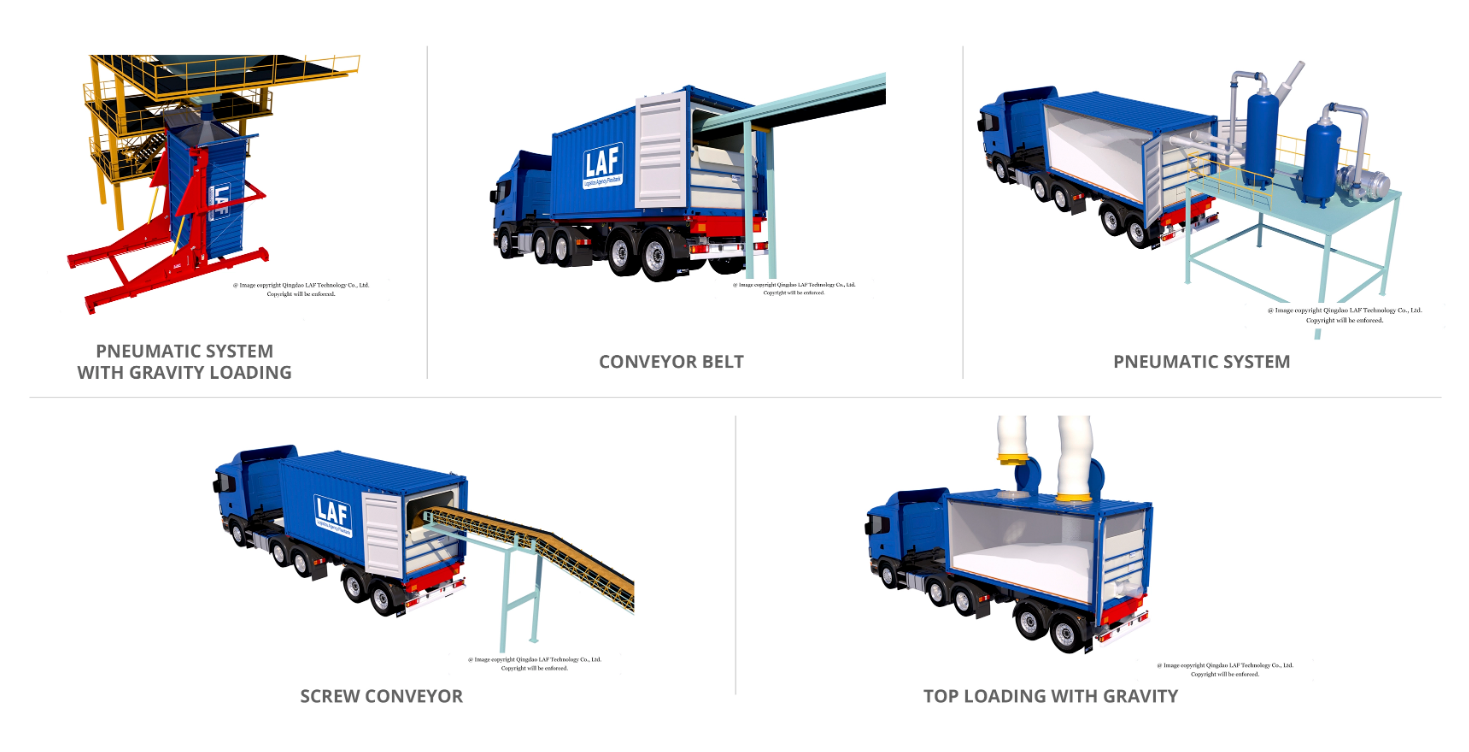

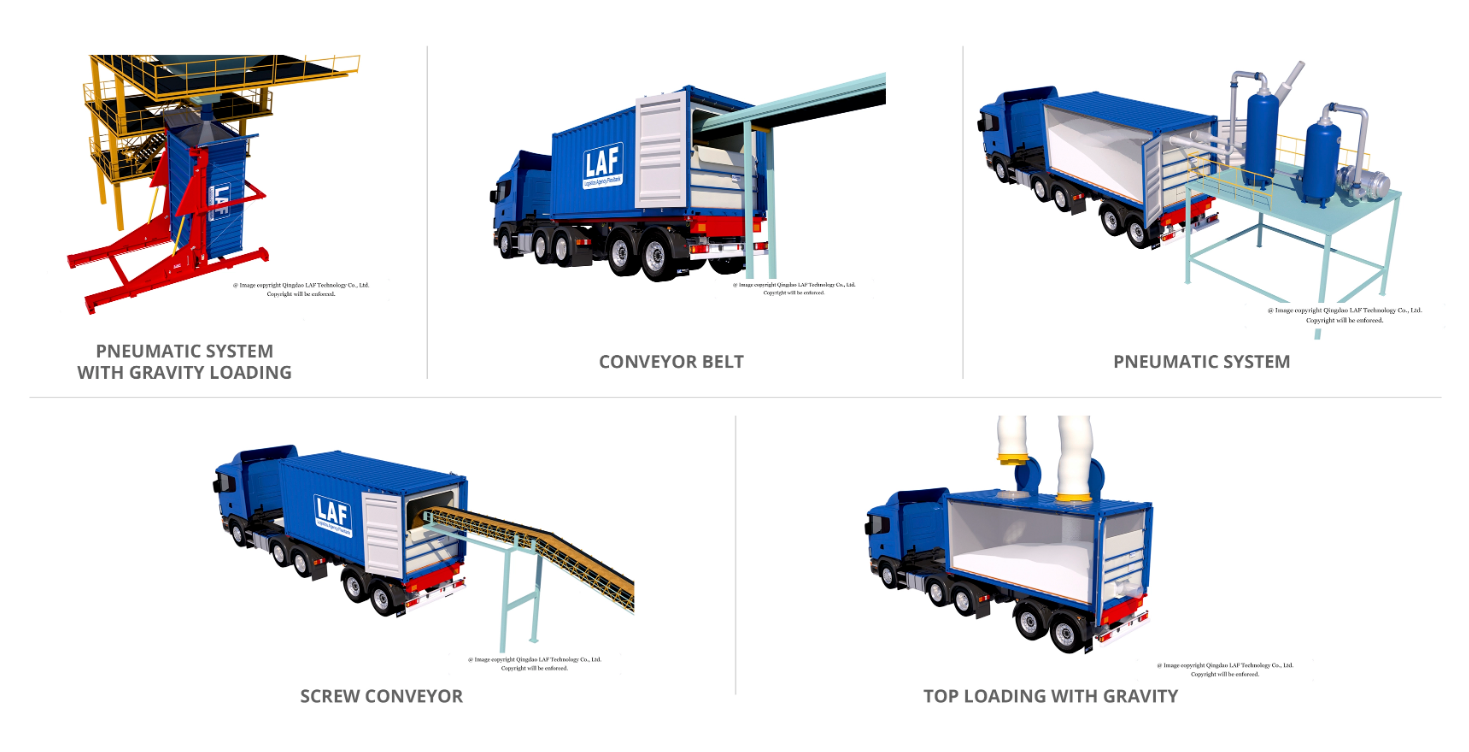

● Can be tailor-made to match different filling and discharging equipment

● Loading/Unloading operation with 45 minutes by 2 operators

● Protect product from damage of moisture and/or contamination

Dry bulk liner is the smartest idea ever for intermodal dry bulk transport, it has been seen as a very efficient and cost-effective alternative to shipping in small packaging such as FIBC, small parcel with capacity ranging from 25kgs to 100kgs and pallets.

Compared to traditional dry bulk transport patterns, containerized dry bulk transport is reducing logistics cost, improving logistics efficiency, and lessen the impact to our environment.

LAF offer Dry Bulk Liners with PE, PP, HDPE, Aluminum materials, and can also design the liner according to container type, physical and chemical properties of cargo, and loading and unloading equipment.

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin,PP resin, PET pellets,PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products

LAF is a worldwide leading manufacturer of economic dry bulk liners, with cutting edge production techniques, offering full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Comprehensive silo-to-silo dry bulk transport solution is designed to suit specific requirements of each client.

It usually starts with a comprehensive assessment of production, storage and transportation of a factory. With senior experience and expertise in bulk commodity supply chain, and our team at LAF DRY BULK LINER DEPT. helps client to optimize their dry bulk logistics cycle with tailor-made dry bulk liners, assistance in development of dry bulk handling equipment for load and unload containers with dry bulk commodities.

● Maximally utilize container space

● Save packaging cost

● Easy to set up

● Can be tailor-made to various containers, e.g. 20’GP, 40’GP, 35’ containers etc.

● Can be tailor-made to match different filling and discharging equipment

● Loading/Unloading operation with 45 minutes by 2 operators

● Protect product from damage of moisture and/or contamination