Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

Product Description

Dry bulk liners, often referred to as container liners, provide a cost-effective method for transporting fluid bulk cargo across vast distances. They effectively utilize the space within standard shipping containers, essentially creating an additional layer of containment.

We specialize in Food Grade Dry Bulk Liners designed for transporting items like flour, starch, salt, and sugar. These liners maintain a dry and sanitary environment for food products throughout their journey. For materials with challenging flow properties, such as flour, our liners are equipped with a floor fluidizing system to facilitate efficient unloading.

Non-hazardous Chemicals: PP resin, PP resin, PET pellets, PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products.

Food: Flour, Starch, Coarse Salt, Granulated Sugar or similar products.

Agricultural Product: Barley, Malts, Grains, Peas, Beans, Lentils, Rice, Cocoa Beans, Fish meal or similar agricultural products.

LAF stands at the forefront as a global leader in producing cost-effective dry bulk liners, employing advanced manufacturing methods and offering comprehensive support for every stage of dry bulk shipping.

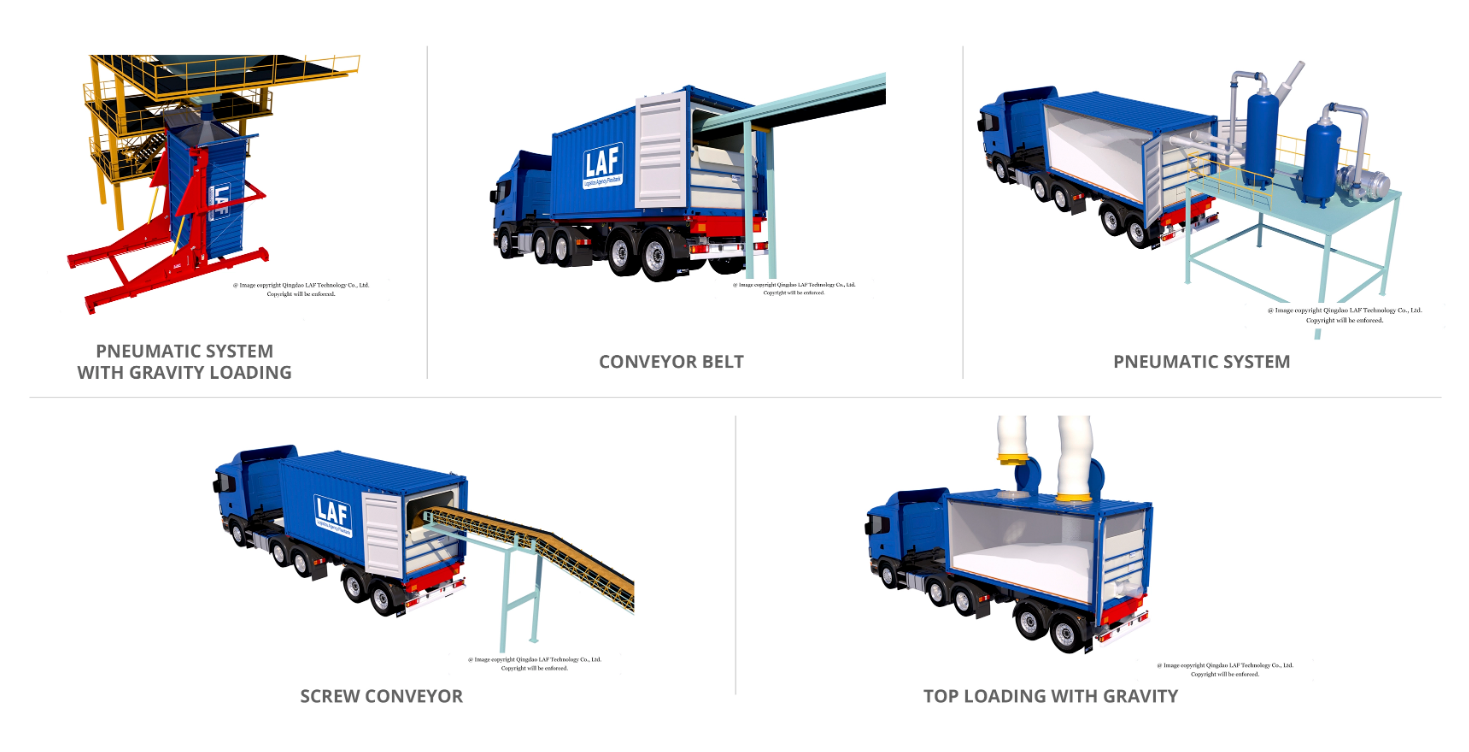

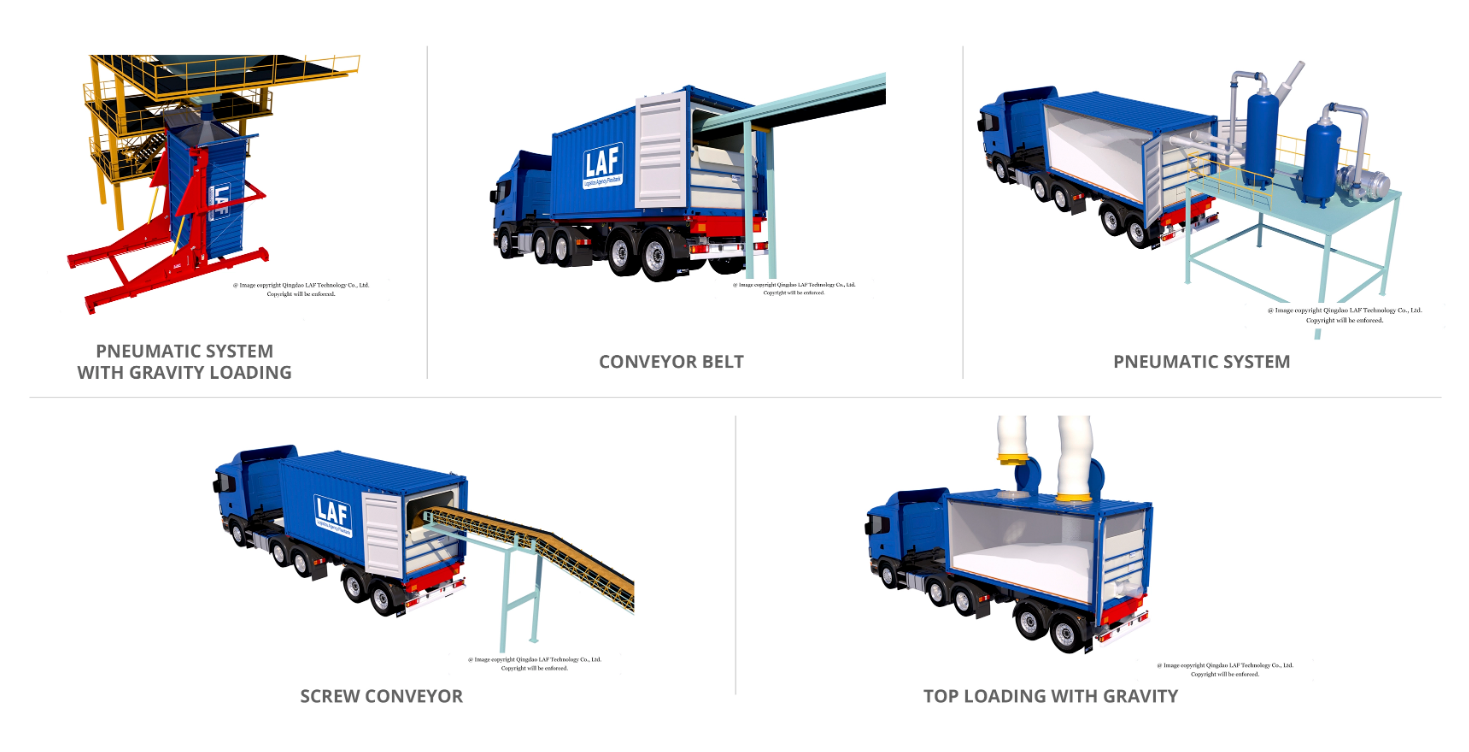

We deliver tailored silo-to-silo transport solutions, precisely crafted to meet each client's unique needs. Our process typically begins with an in-depth evaluation of a factory's production, storage, and transportation operations. Leveraging our deep expertise in bulk commodity logistics, our dedicated team at the LAF Dry Bulk Liner Department assists clients in streamlining their dry bulk supply chain. We provide custom liners and support the development of specialized handling equipment to facilitate efficient loading and unloading of dry bulk cargoes.

● Maximally utilize container space

● Save packaging cost

● Easy to set up

● Can be tailor-made to various containers, e.g. 20'GP, 40'GP containers etc.

● Can be tailor-made to match different filling and discharging equipment

● Loading/Unloading operation with 45 minutes by 2 operators

● Protect product from damage of moisture and/or contamination

Product Description

Dry bulk liners, often referred to as container liners, provide a cost-effective method for transporting fluid bulk cargo across vast distances. They effectively utilize the space within standard shipping containers, essentially creating an additional layer of containment.

We specialize in Food Grade Dry Bulk Liners designed for transporting items like flour, starch, salt, and sugar. These liners maintain a dry and sanitary environment for food products throughout their journey. For materials with challenging flow properties, such as flour, our liners are equipped with a floor fluidizing system to facilitate efficient unloading.

Non-hazardous Chemicals: PP resin, PP resin, PET pellets, PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products.

Food: Flour, Starch, Coarse Salt, Granulated Sugar or similar products.

Agricultural Product: Barley, Malts, Grains, Peas, Beans, Lentils, Rice, Cocoa Beans, Fish meal or similar agricultural products.

LAF stands at the forefront as a global leader in producing cost-effective dry bulk liners, employing advanced manufacturing methods and offering comprehensive support for every stage of dry bulk shipping.

We deliver tailored silo-to-silo transport solutions, precisely crafted to meet each client's unique needs. Our process typically begins with an in-depth evaluation of a factory's production, storage, and transportation operations. Leveraging our deep expertise in bulk commodity logistics, our dedicated team at the LAF Dry Bulk Liner Department assists clients in streamlining their dry bulk supply chain. We provide custom liners and support the development of specialized handling equipment to facilitate efficient loading and unloading of dry bulk cargoes.

● Maximally utilize container space

● Save packaging cost

● Easy to set up

● Can be tailor-made to various containers, e.g. 20'GP, 40'GP containers etc.

● Can be tailor-made to match different filling and discharging equipment

● Loading/Unloading operation with 45 minutes by 2 operators

● Protect product from damage of moisture and/or contamination