Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

Dry Bulk Liners, also known as container liners, provide the most cost-effective solution for transporting and temporarily storing dry cargo. These liners create a protective barrier between the product and the container's interior, reducing the risk of product quality degradation and preventing contamination.

For food products such as flour, starch, coarse salt, granulated sugar, etc., we offer Food Grade Dry Bulk Liners to ensure that food is stored in a dry and clean environment during transportation. When transporting commodities with poor flow characteristics, such as flour, which can be difficult to discharge, a fluidizing system is integrated into the dry bulk liner on the container floor to enhance discharge efficiency.

LAF provides Dry Bulk Liners made from PE, PP, HDPE, and Aluminum materials. We can also customize the liner based on the container type, the physical and chemical properties of the cargo, and the loading and unloading equipment used.

Sugar, Malt, Rice, Soya beans, Grain, Pulses, Wheat /Flakes, Oats/ Flakes, Nuts, Seeds, Citric Acid, Coffee beans, Cocoa, Potatoes /Flour/Flakes, Salt, Etc.

PTA, Nylon Polymers, PP Resin, PVC Resin, Aluminium powder, Pigments, Minerals, Polyester granules, PE & PP granules, Polycarbonate granules, ABS Resin, Colorants, Starches, Detergents, Polystyrene granules, Etc.

LAF is a global leader in manufacturing cost-effective dry bulk liners, utilizing advanced production techniques and providing comprehensive service and technical support for all aspects of dry bulk commodity shipments.

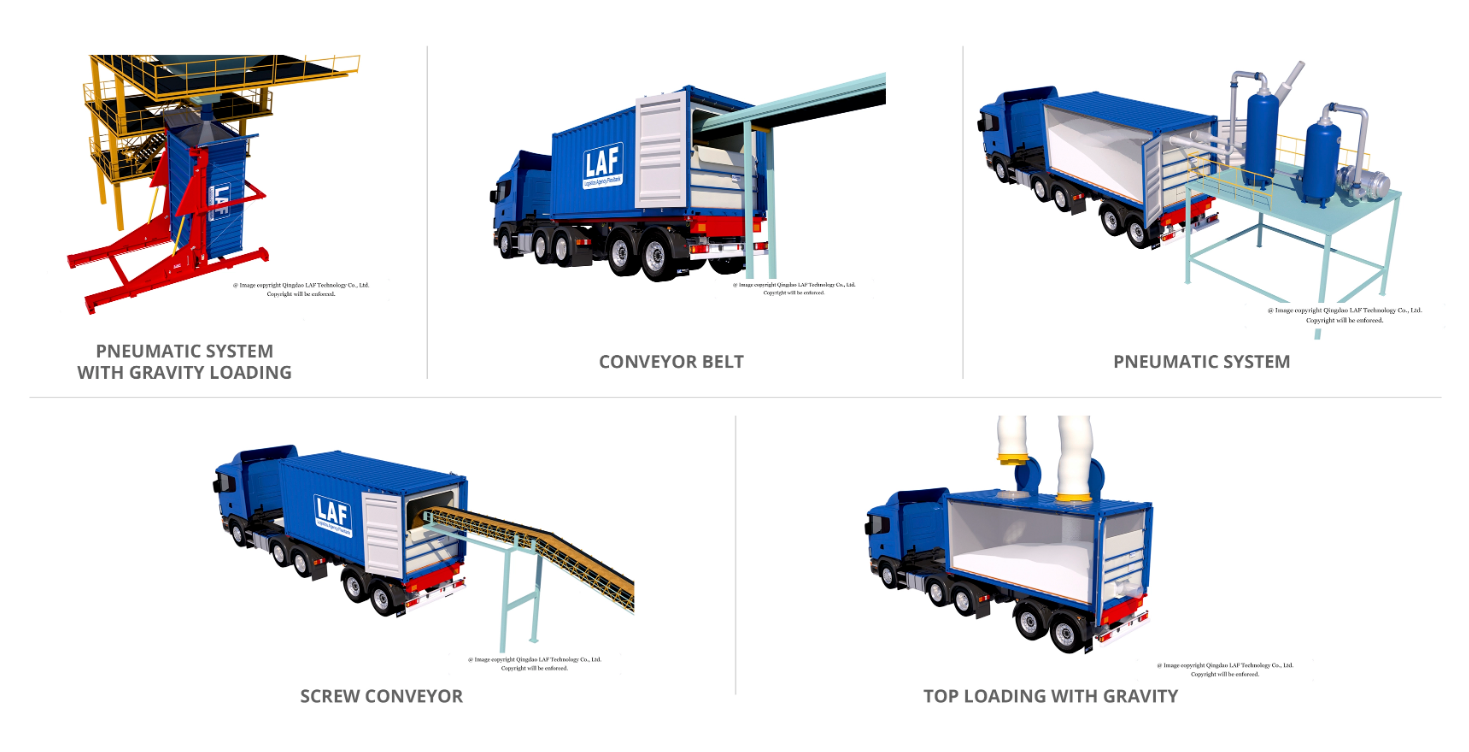

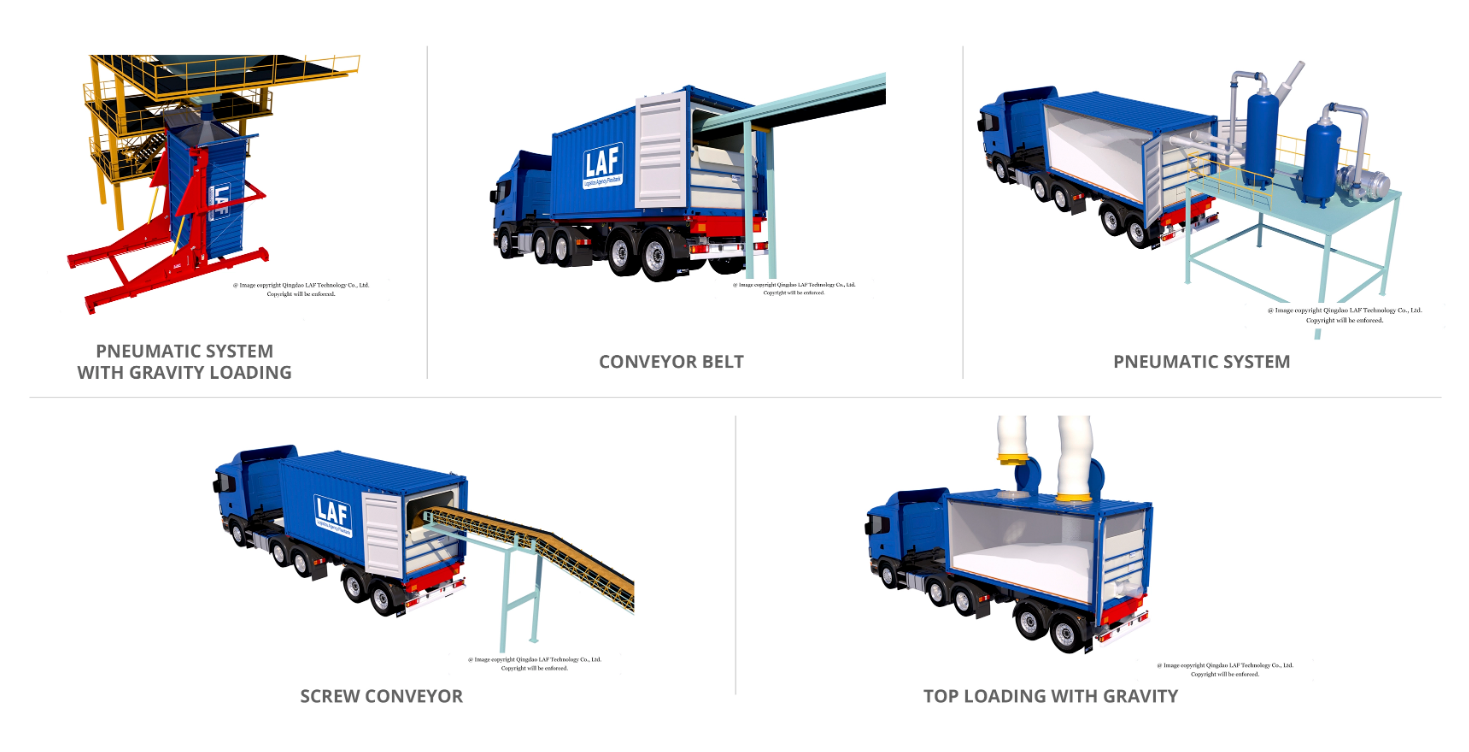

Our process typically begins with a thorough evaluation of a factory's production, storage, and transportation needs. With extensive experience and expertise in the bulk commodity supply chain, the team at LAF DRY BULK LINER DEPT. assists clients in optimizing their dry bulk logistics by offering customized dry bulk liners and support in developing handling equipment for loading and unloading dry bulk commodities.

● Major advantage of using container liners is that they are very easy to install and require up to 1 or 2 people to complete the installation process without investing too much time or effort.

● In addition, it only takes about 1 hour to fill the goods at place of departure or unload the goods at the destination.

● Compared with the traditional bags, it completely realizes the door-to-door transportation method: eliminating the links of traditional labor filling, moving to the warehouse, packing into the container, and unloading the container to the storage warehouse, thereby it improved efficiency and saved logistics costs.

● In addition to the reduction of logistics links, it can secure the integrity of the goods and reduce cargo losses.

● Besides, because of its excellent sealing and easy disassembly function, compared with bare loading in containers, the cargo residue will be much reduced after unloading from liner bag.

● As a package, it can protect the goods inside. Some dry bulk food commodities have strict sanitary conditions. In this case, the dry bulk container liner bag is used firstly because the liner bag itself can be a food-grade hygiene standard, the second is that it can effectively avoid the invasion of external environmental pollutants during transportation. In addition, it can play a role in moisture-proof.

● For some goods that are easy to pollute containers, such as carbon black, the use of dry bulk container liners can prevent pollution of the container walls and cross-contamination with previously loaded goods, thereby reducing cleaning costs and improving the turnover rate of containers.

Dry Bulk Liners, also known as container liners, provide the most cost-effective solution for transporting and temporarily storing dry cargo. These liners create a protective barrier between the product and the container's interior, reducing the risk of product quality degradation and preventing contamination.

For food products such as flour, starch, coarse salt, granulated sugar, etc., we offer Food Grade Dry Bulk Liners to ensure that food is stored in a dry and clean environment during transportation. When transporting commodities with poor flow characteristics, such as flour, which can be difficult to discharge, a fluidizing system is integrated into the dry bulk liner on the container floor to enhance discharge efficiency.

LAF provides Dry Bulk Liners made from PE, PP, HDPE, and Aluminum materials. We can also customize the liner based on the container type, the physical and chemical properties of the cargo, and the loading and unloading equipment used.

Sugar, Malt, Rice, Soya beans, Grain, Pulses, Wheat /Flakes, Oats/ Flakes, Nuts, Seeds, Citric Acid, Coffee beans, Cocoa, Potatoes /Flour/Flakes, Salt, Etc.

PTA, Nylon Polymers, PP Resin, PVC Resin, Aluminium powder, Pigments, Minerals, Polyester granules, PE & PP granules, Polycarbonate granules, ABS Resin, Colorants, Starches, Detergents, Polystyrene granules, Etc.

LAF is a global leader in manufacturing cost-effective dry bulk liners, utilizing advanced production techniques and providing comprehensive service and technical support for all aspects of dry bulk commodity shipments.

Our process typically begins with a thorough evaluation of a factory's production, storage, and transportation needs. With extensive experience and expertise in the bulk commodity supply chain, the team at LAF DRY BULK LINER DEPT. assists clients in optimizing their dry bulk logistics by offering customized dry bulk liners and support in developing handling equipment for loading and unloading dry bulk commodities.

● Major advantage of using container liners is that they are very easy to install and require up to 1 or 2 people to complete the installation process without investing too much time or effort.

● In addition, it only takes about 1 hour to fill the goods at place of departure or unload the goods at the destination.

● Compared with the traditional bags, it completely realizes the door-to-door transportation method: eliminating the links of traditional labor filling, moving to the warehouse, packing into the container, and unloading the container to the storage warehouse, thereby it improved efficiency and saved logistics costs.

● In addition to the reduction of logistics links, it can secure the integrity of the goods and reduce cargo losses.

● Besides, because of its excellent sealing and easy disassembly function, compared with bare loading in containers, the cargo residue will be much reduced after unloading from liner bag.

● As a package, it can protect the goods inside. Some dry bulk food commodities have strict sanitary conditions. In this case, the dry bulk container liner bag is used firstly because the liner bag itself can be a food-grade hygiene standard, the second is that it can effectively avoid the invasion of external environmental pollutants during transportation. In addition, it can play a role in moisture-proof.

● For some goods that are easy to pollute containers, such as carbon black, the use of dry bulk container liners can prevent pollution of the container walls and cross-contamination with previously loaded goods, thereby reducing cleaning costs and improving the turnover rate of containers.