Tel: +86-(0)532 6609 8998

| Availability: | |

|---|---|

Product Description

Dry Bulk liners are manufactured in a clean and hygiene environment, and are made with strong, durable, food-grade co-extruded virgin PE, PP, HDPE materials.

Dry Bulk Liner have been the best solution for bulk non-hazardous free flowing pellets, granules, and powder, compared with traditional jumbo bags or even small PP woven bags, it makes containerized transportation of bulk solid materials efficient, and cost-effective.

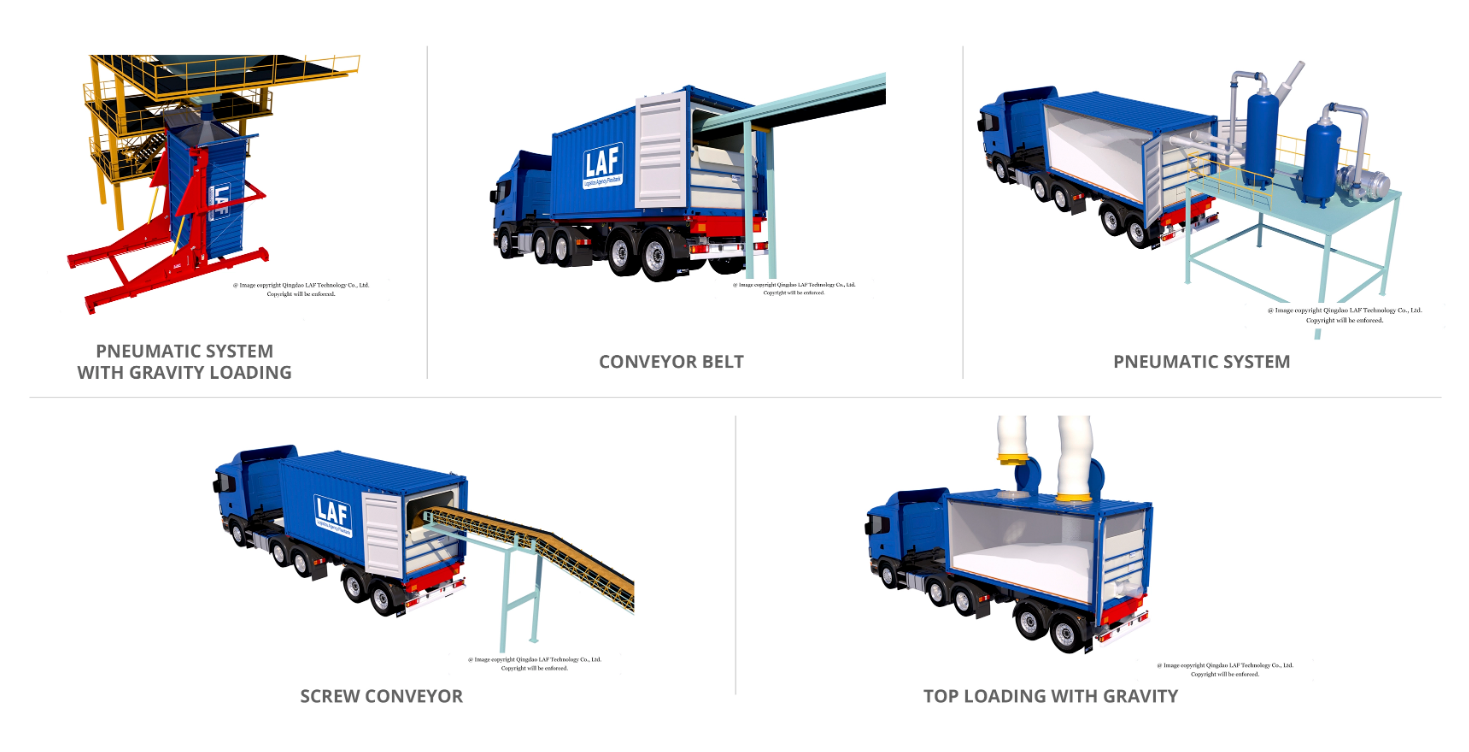

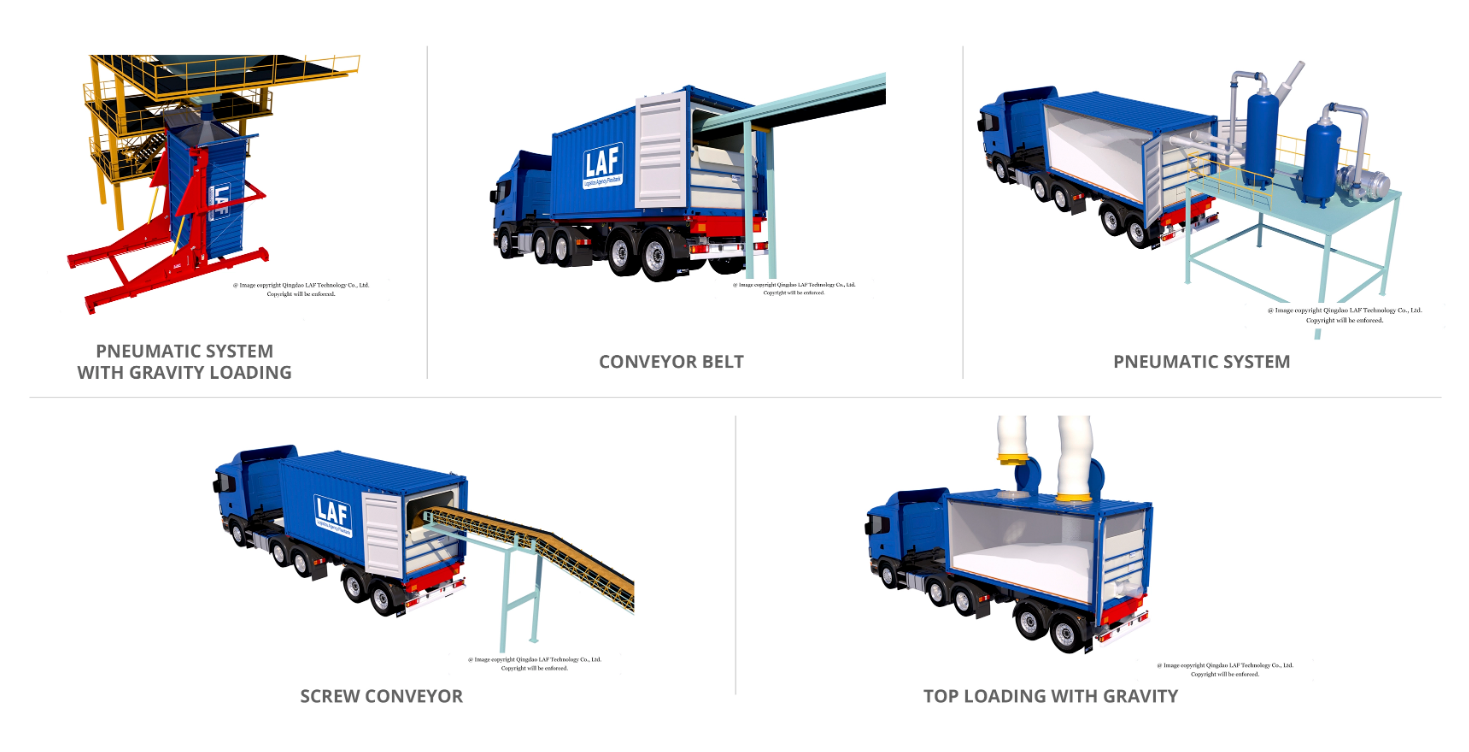

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin, PP resin, PET pellets, PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products

LAF is a worldwide leading manufacturer of economic dry bulk liners, with cutting edge production techniques, offering full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Comprehensive silo-to-silo dry bulk transport solution is designed to suit specific requirements of each client.

It usually starts with a comprehensive assessment of production, storage and transportation of a factory. With senior experience and expertise in bulk commodity supply chain, and our team at LAF DRY BULK LINER DEPT. helps client to optimize their dry bulk logistics cycle with tailor-made dry bulk liners, assistance in development of dry bulk handling equipment for load and unload containers with dry bulk commodities.

What commondities can dry bulk liner carry?

LAF Dry Bulk Liner can carry dry granular, flaked, pellet or powder products, and protecting products from contamination and safeguard the integrity of the commodities.

How long time to fit a dry bulk liner?

Two workers can install the dry bulk liner in 15 minutes.

How to load a dry bulk liner?

Dry commodity would be loaded inside the dry bulk liner with automatic loading system (pneumatic, belt/screw conveyor or gravity) quickly. When it reaches the target payload volume, container doors would be closed and secured. The loaded container would be dispatched to destination via truck, rail, or ship.

How to unload a dry bulk liner?

Keep container left door closed, and open the right container door. Connect the discharging manifold to the discharge spout of dry bulk liner, and then attach the automatic discharging equipment to it, after that start equipment to discharge.

What certificates you have?

FDA, EC, Kosher, Halal, FSSC22000, ISO9001

LAF offer complete non-hazardous chemical transport packaging solution, from compatibility analysis, packaging product design, container inspection and installation, used package recycle and disposal. Packages we offer, like Flexitank, Dry Bulk Liner, and Collapsible IBC, though as designed as single-trip disposal product, but all are made from recyclable plastic, steel and carton materials.

Product Description

Dry Bulk liners are manufactured in a clean and hygiene environment, and are made with strong, durable, food-grade co-extruded virgin PE, PP, HDPE materials.

Dry Bulk Liner have been the best solution for bulk non-hazardous free flowing pellets, granules, and powder, compared with traditional jumbo bags or even small PP woven bags, it makes containerized transportation of bulk solid materials efficient, and cost-effective.

Customized dry bulk liner is provided according to specific cargo features, loading machine in supplier factory as well as unloading machine in cargo receiver factory.

PP resin, PP resin, PET pellets, PTA powder, PVC powder, Alumina powder, Cement, Carbon black powder, or similar products

LAF is a worldwide leading manufacturer of economic dry bulk liners, with cutting edge production techniques, offering full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Comprehensive silo-to-silo dry bulk transport solution is designed to suit specific requirements of each client.

It usually starts with a comprehensive assessment of production, storage and transportation of a factory. With senior experience and expertise in bulk commodity supply chain, and our team at LAF DRY BULK LINER DEPT. helps client to optimize their dry bulk logistics cycle with tailor-made dry bulk liners, assistance in development of dry bulk handling equipment for load and unload containers with dry bulk commodities.

What commondities can dry bulk liner carry?

LAF Dry Bulk Liner can carry dry granular, flaked, pellet or powder products, and protecting products from contamination and safeguard the integrity of the commodities.

How long time to fit a dry bulk liner?

Two workers can install the dry bulk liner in 15 minutes.

How to load a dry bulk liner?

Dry commodity would be loaded inside the dry bulk liner with automatic loading system (pneumatic, belt/screw conveyor or gravity) quickly. When it reaches the target payload volume, container doors would be closed and secured. The loaded container would be dispatched to destination via truck, rail, or ship.

How to unload a dry bulk liner?

Keep container left door closed, and open the right container door. Connect the discharging manifold to the discharge spout of dry bulk liner, and then attach the automatic discharging equipment to it, after that start equipment to discharge.

What certificates you have?

FDA, EC, Kosher, Halal, FSSC22000, ISO9001

LAF offer complete non-hazardous chemical transport packaging solution, from compatibility analysis, packaging product design, container inspection and installation, used package recycle and disposal. Packages we offer, like Flexitank, Dry Bulk Liner, and Collapsible IBC, though as designed as single-trip disposal product, but all are made from recyclable plastic, steel and carton materials.